1、Product Introduction

Hand-held X-ray flaw detector for steel-cord conveyor belt is a small X-ray machine for perspective purpose by imaging with X-ray principle, which is specially used for perspective inspection of steel-cord conveyor belt of mining companies. By inserting the flaw detector parallel to the ends of the upper and lower surfaces of the conveyor belt and switching on the power of flaw detector, the wire cables inside the conveyor belt can be clearly displayed. Different damages, such as wire breakage, wear, fatigue, rust and joint twitch, inside the steel-cord conveyor belt can be clearly detected through the display screen of the flaw detector, and the defective parts of the steel-cord can be photographed for storage and remote transmission.

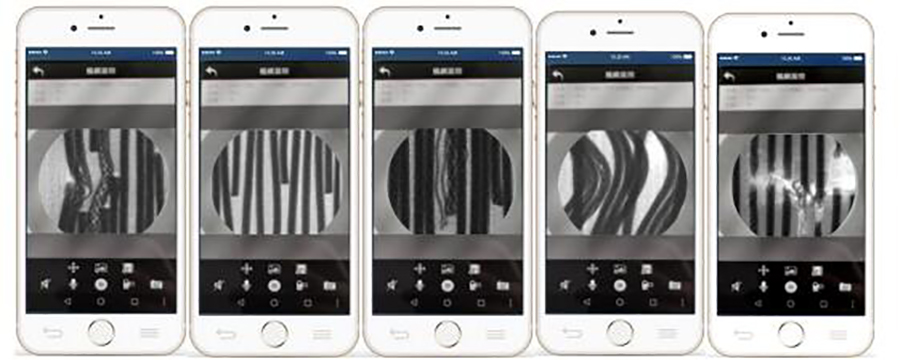

The detection site can be observed in time through the built-in display screen.

Remote observation can be realized through wireless connection with mobile phone/tablet/laptop

2、Working Principle

The hand-held X-ray flaw detector for steel-cord conveyor belt is mainly composed of X-ray tube, power supply and control circuit, of which the X-ray tube is composed of cathode filament (Cathod), anode target (Anode) and vacuum glass tube, which provides high voltage electric field to accelerate the flow of active electrons on the filament to the cathode, thus generating a high-speed electronic flow. The high-speed electronic flow penetrates the object, generates perspective picture through the X-ray image intensifier, and transmits the image generated to the remote image viewing device through the designated interface. The image can be clearly displayed and stored in the display interface.

3、Features

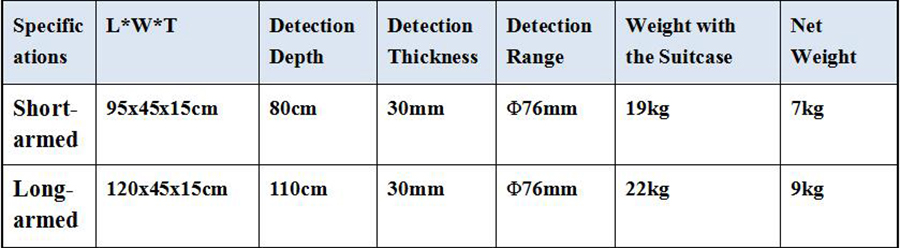

(1)Small size: L550mm*W420mm*T130mm

(2)Light weight: the weight of the detector is 7kg, and the total weight including the suitcase is 19kg

(3) Clear imaging: the detection card, with a resolution of 50 lp/cm, can take the complete photo of every subtle link of the entire belt

(4)Pictures can be stored: the detected damages can be photographed by pressing the shutter, with the damage data stored in the memory card in the form of pictures for easy playback and storage.

(5)Diverse image viewing devices: The detector transmits signals to image viewing devices, such as mobile phone/tablet/laptop, wirelessly

(6) Low radiation: Radiation at any angle 1M away from the X-ray tube will not jeopardize human health

(7)Low price: It is the cheapest X-ray flaw detector for steel-cord conveyor belt on the market

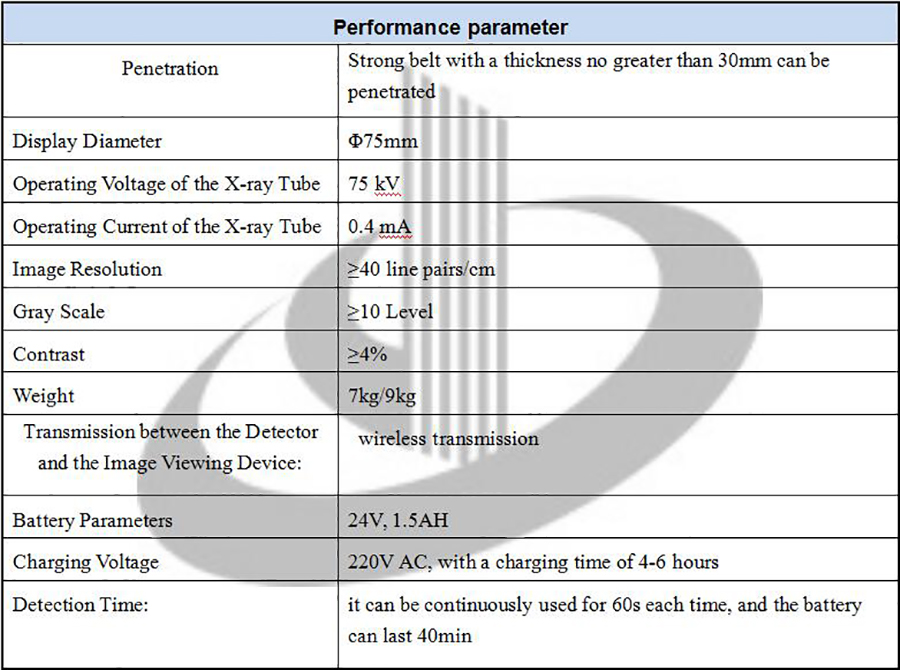

4、Technical Indicators

5、There are two models of this products: Long-armed and Short-armed

6、Maintenance

(1)As the outer shell of the product is made of metal, and the internal parts are basically electronic components, there is no wear and tear, without need for maintenance.

However, it should be pointed out that the service life of the ray generator is limited. Ideally, its service life is 15,000 hours.

(2)Surface contamination shall be cleaned by crocus cloth dipped with detergent. Alcohol or acid reagent shall not be used to wipe the surface of detector in order to avoid damaging its surface smoothness.

(3)Please handle the product gently when using it. Any bump, which will cause permanent damage to the display screen and affect the service life of the ray generator, is especially forbidden.

7、Comparison of advantages and disadvantages among the three types of X-ray detectors for steel-cord conveyor belt

(SCAN)

(SCAN)